Machine Monitoring That Is Both Simple and Can Go Beyond Running or Not Running

Scytec DataXchange has many features that seperate it from other machine monitoring platforms. One of which is the way Scytec DataXchange machine monitoring talks to your machines.

By utilizing industry-wide smart factory standard connection methods like MTConnect, OPC UA, Fanuc FOCAS, Okuma THINC and more, DataXchange connects to everything on your shop floor. When DataXchange gets talking to your machines you can start solving all your shop floor woes by tackling a lot more than just machine downtime.

Read more below or see how with a DEMO.

From must-have metrics to powerful extras, machine monitoring that goes beyond expectations.

With support for MTConnect, Fanuc FOCAS, OPC UA, Okuma THINC, Heidenhain TNC, Siemens Solution Line, Siemens One, the Mazak Smooth series, and a variety of hardware modules and sensors, Scytec DataXchange OEE software delivers unmatched data collection flexibility.

DataXchange has the ability to communicate with a majority of machine brands and types and can retrieve a plethora of information that solves your shop floor issues. Scytec DataXchange is a smarter factory solution than other machine monitoring platforms.

DataXchange Can Collect Data From Anything, Including Common Controls and Protocols From Brands Like…

What Are Scytec DataXchange’s Advanced Collection Methods?

Watch this short video to see how Scytec DataXchange machine monitoring can utilize the best of IIoT connection methods to pull the richest set of machine data so you can confront and conquer your shop floor issues.

DataXchange’s advanced data collection allows you to dictate your smart factory experience!

Connect To Everything

Scytec DataXchange ensures you can monitor every piece of equipment in your shop floor.

Solve Your Specific Problems

With DataXchange’s rules for data collection you get the means to solve your specific problems.

Retrieve the Most Useful Information

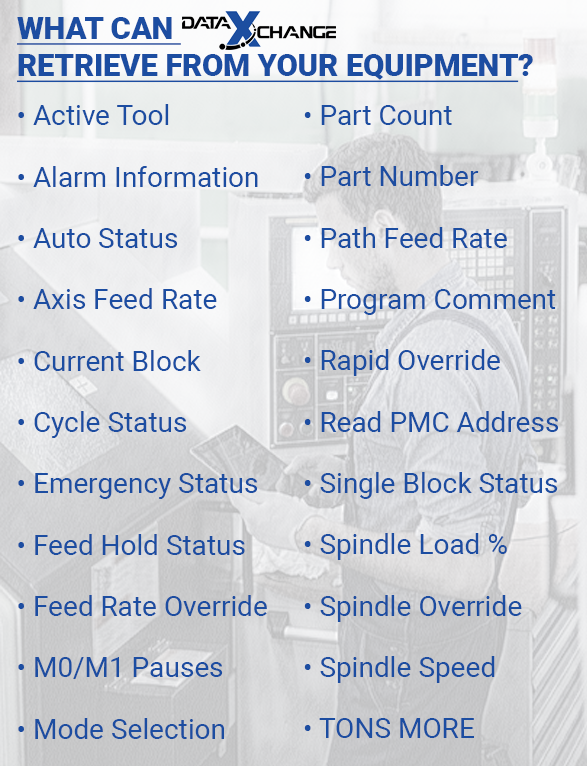

DataXchange can tell you more that just machine downtime, take a look at the list on the left.

Contact Scytec

Essential reporting, with deep insights is only a demo away.

Manufacturers should reach out to Scytec to get expert answers on how real-time machine monitoring can reduce downtime, improve productivity, and deliver fast ROI with an affordable, scalable solution.

Contact Scytec Sales: 720-482-8250 or sales@scytec.com

Why DataXchange?

Not all machine monitoring platforms are created equal. Discover what sets Scytec DataXchange apart and why it’s the smart choice for your factory.

ROI In No Time

Your Scytec DataXchange machine monitoring platform can have a return on investment in just the first few days of the month with ease.

Scalable Options

Scytec DataXchange follows the principle of “grow with your data,” offering tiered features so manufacturers can scale seamlessly.

Adaptable Rules That Solve Your Issues

One of the most powerful and unique advantages of Scytec DataXchange is its ability to let users define custom rules for how data is collected from their shop floor equipment, based on their specific production needs.

DataXchange Monitors All

Your shop floor probably doesn’t run on just one machine type, and neither should your monitoring system. Scytec DataXchange connects to a wide range of machines.

Scytec DataXchange

Data that matters, and data that delivers results. DEMO NOW!

DATAXCHANGE VS OTHER MACHINE MONITORING PLATFORMS

|

DataXchange can connect to everything |

Others can only connect to specific machines |

|

DataXchange offers many deployments types |

Others offer only cloud storage |

|

DataXchange has no minimum order for machines |

Others have high minimum orders for machines |

|

DataXchange offers unlimited users and locations on one account |

Others do not offer unlimited users |

|

DataXchange is affordable, starting at $52 a machine |

Others are a lot more costly |

|

Scytec professionals can come on site for implementation |

Others only offer over the phone support |

|

DataXchange integrates with Vericut |

No other platform integrates with Vericut |

|

DataXchange can retrieve tons of information off machines |

Others can only let you know about machine downtime |

|

DataXchange offers endless configurability for dashboards |

Others are limited in their offerings for reporting |

Unlocking the Hidden Power Inside Your CNC Controller

Did you know your CNC controller holds a hidden wealth of data, information that can dramatically improve OEE, reduce downtime, and reveal powerful insights about your production process?

Most manufacturers only scratch the surface of what their CNC machines can tell them. With Scytec DataXchange, you can tap into that buried intelligence and turn it into real-time metrics, dashboards, and actionable insights that drive continuous improvement across your shop floor.

This article explores how DataXchange accesses and uses data from your CNC controller to elevate efficiency and uncover the true potential of your equipment.

What Exactly Is a CNC Controller?

Think of your CNC controller as the brain of your machine. It interprets programmed instructions (G-code), converts them into precise electrical signals, and guides every tool movement that brings a part to life.

In essence, it’s the bridge between your digital design and physical production. DataXchange connects to these controllers using communication standards such as MTConnect, OPC UA, or Fanuc FOCAS to extract valuable information. This allows manufacturers to see exactly how their machines are performing, not just if they’re running, but how well they’re running.

How Machine Monitoring Works

If you’re new to machine monitoring, here’s a quick overview:

A platform like Scytec DataXchange collects live data from CNC controllers via open or direct protocols (e.g., MTConnect, Fanuc FOCAS, Okuma THINC) and translates that into clear visualizations.

Rather than relying on manual logs or operator notes, DataXchange automatically captures and displays:

- Real-time machine status and cycle data

- Downtime tracking and OEE calculations

- Operator feedback for context (like breaks or maintenance events)

- Insights from sensors and connected devices

The result? Real-time dashboards viewable from any device, smartphones, tablets, shop TVs, or computers, giving teams immediate visibility and the ability to respond faster to issues, boost performance, and meet production goals.

The DataXchange Advantage

What sets Scytec DataXchange apart is its direct access to native CNC controller protocols from industry-leading brands like Fanuc, Okuma, Siemens, Heidenhain, Haas NGC, and Mazak.

This direct connection goes far beyond what basic or standardized protocols can provide. It enables deeper visibility into critical machine states and metrics such as:

- Active tool positions

- Alarm codes and descriptions

- Coolant and dry-run status

- Emergency stop conditions (E-Stop)

- M0 pause or hold states

- And much more

These rich data points not only enhance monitoring within DataXchange but also integrate seamlessly with CNC Machine Connect, the interface between Scytec DataXchange and Vericut, allowing for closed-loop verification and simulation workflows.

Why Direct Protocols Deliver Deeper Insight

While open standards like MTConnect are useful, they have limitations. They often provide only a subset of the data available from your CNC controller and lack the full diagnostic or status-level detail needed for advanced analytics.

Additionally, open protocols typically aren’t supported by OEMs or third parties, which can make fixing bugs or enhancing functionality difficult.

By contrast, direct protocol access through DataXchange provides:

- Full data depth directly from the source

- Vendor-backed support and updates

- Faster issue resolution and compatibility with OEM enhancements

This means you’re not limited to surface-level machine data, you’re unlocking everything your CNC controller knows about how your machines, operators, and processes are performing.

Reveal the Secrets Hidden in Your CNC Controller

Your CNC machines already hold the insights you need to optimize performance, you just need the right technology to reveal them.

With Scytec DataXchange, manufacturers can finally see what’s been hidden all along: detailed, real-time machine intelligence that drives smarter decisions, leaner operations, and measurable improvement across the shop floor. Start uncovering the secrets inside your CNC controller and turn hidden data into your next competitive advantage.